A collaborative aerospace initiative led in part by Airbus has demonstrated that high-performance thermoplastic composite aircraft parts can be given a second operational life, marking a significant step forward for circular economy practices in aviation. By helping to engineer the technical framework behind the project, Airbus worked alongside multiple industry partners to prove that composite structures from retired aircraft can be successfully repurposed for continued use.

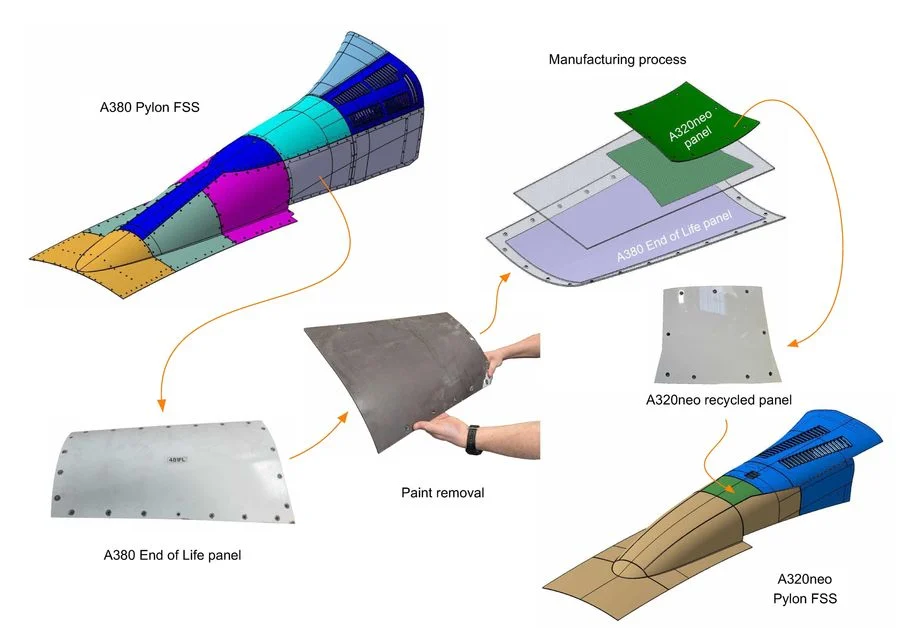

The work focused on the reuse of a thermoplastic composite component originally installed on an A380 aircraft. Once the aircraft reached the end of its service life, the engine pylon fairing cover was recovered and transformed into a smaller, equivalent part suitable for installation on an A320neo. Airbus played a key role in scientifically validating the reuse process and coordinating the consortium, while specialist partners contributed expertise spanning material characterisation, reshaping, manufacturing and certification.

The consortium brought together Airbus, Toray Advanced Composites, Daher and TARMAC Aerosave, illustrating how collaboration across the aerospace supply chain can enable circular solutions in an industry where composite materials are increasingly prevalent but challenging to recycle. The resulting repurposed component meets the same quality and mechanical performance standards as a newly manufactured panel, suggesting potential for scalable adoption across both new production and retrofit programmes.

The initiative received international recognition at the JEC Composites Innovation Awards, an annual competition that attracts more than 170 entries from across multiple industries. In the circularity and recycling category, the award was presented to Toray, the developer and manufacturer of the original thermoplastic composite material used for the A380 part.

“This recognition from the JEC shows how complex challenges, including high-value recycling, are best tackled through partnership. We exist in a complex aerospace supply chain in a hyper-connected world. If a company comes up with a solution on its own, that’s a great story. If an entire industry does it together, that’s transformative, since it can lead to something bigger!”

– Isabell Gradert, Airbus VP Central Research and Technology.

Airbus has a strong track record at the JEC awards and contributed to several prize-winning and shortlisted projects in recent years, including additional initiatives linked to thermoplastic composites. Insights gained from this latest programme will feed directly into Airbus’ eco-design strategy, which aims to ensure future aircraft components are designed from the outset to support material recovery, reuse and reduced environmental impact at end of life.

With aircraft such as the A380 containing thousands of flying parts made from thermoplastic composites, the need for viable recycling and reuse solutions is becoming increasingly pressing. By helping to engineer and demonstrate a practical pathway for high-value composite repurposing, Airbus and its partners have shown how coordinated industry action can support reduced waste, lower energy consumption and a more circular approach to aerospace manufacturing.

If you are interested in meeting companies advancing sustainable solutions and collaboration across the aviation supply chain, contact us today about our MTB Aviation events.