The American Bureau of Shipping (ABS) has reinforced its role at the forefront of maritime innovation through a pair of key initiatives in partnership with HD Hyundai affiliates, advancing both digital transformation in shipbuilding and sustainable energy solutions for the maritime sector.

In a major move toward next-generation shipbuilding, ABS and HD Hyundai Samho have signed a memorandum of understanding (MoU) to pursue joint development of an artificial intelligence (AI)-driven smart shipyard. This collaboration will explore the use of emerging technologies, including robotics, AI, and automation, to enhance efficiency, safety, and productivity across the shipyard’s operations. As part of the project, ABS will apply its comprehensive Guide for Smart Technologies for Shipyards to support the implementation process.

“Advanced technologies are transforming shipyard operations and opening new avenues for progress. Intelligent systems show promise for elevating health, safety and quality standards, driving efficiency and innovation in contemporary shipbuilding. We welcome this opportunity to work with HD Hyundai Samho to explore new applications of smart technologies to optimise shipyard operations.”

Christopher J. Wiernicki, ABS Chairman and CEO.

HD Hyundai Samho is taking a bold step forward in its digital journey.

“HD Hyundai Samho is standing at the centre of the digital transformation crossroad. We should move forward from shipbuilding automation and digitalisation to AI and data-driven decision-making for survival. This AI-based digital transformation will not be achieved without appropriate collaborations. HD Hyundai Samho and ABS are working together to identify the right technologies and strategies to enhance the future of shipbuilding.”

Hwan-Gyu Kim, HSHI Senior Executive Vice President and Chief Operating Officer.

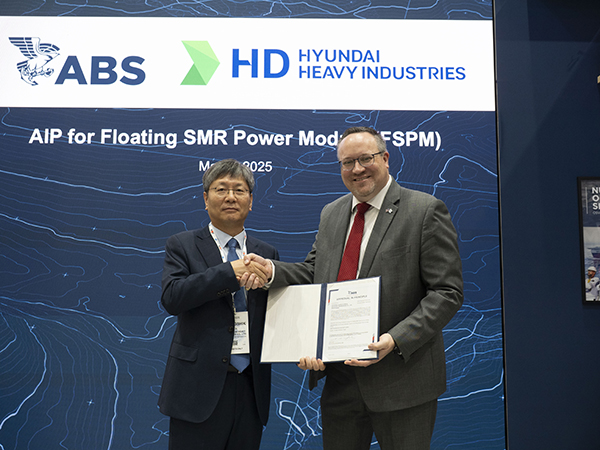

In parallel with this initiative, ABS has granted Approval in Principle (AIP) to HD Hyundai Heavy Industries (HHI) and HD Korea Shipbuilding & Offshore Engineering (HD KSOE) for a cutting-edge floating small modular reactor (SMR) power platform. Designed to supply low-carbon energy near coastal and offshore regions, the platform could serve a variety of uses, from powering ports to supporting coastal infrastructure and communities.

“Floating nuclear power facilities show promise in supporting power grids, microgrids, industrial and port operations, data centres, and other uses,. Today’s advanced nuclear technology has a different risk profile from traditional reactor technology with state-of-the-art designs and lower enrichment fuels, making commercial offshore and maritime applications more viable.”

Patrick Ryan, ABS Senior Vice President and Chief Technology Officer.

Wiernicki emphasised the financial and environmental potential of this technology, stating,

“When you account for fuel differentials, the cost of compliance and residual value, it costs roughly the same as fossil options, only with zero carbon operations. And it gets much more attractive when compared to the high cost of green fuels.”

The new barge-based design represents a flexible solution to longstanding infrastructure challenges in the nuclear space.

“This barge design not only eliminates the inconvenience of selecting onshore sites by being installed at sea but also offers the advantage of an integrated design for thermal energy production. This increases the potential to support the production of eco-friendly ship fuels like ammonia or methanol.”

Dr. Kim Sung-Jun, Director of Future Technology at HD KSOE.

Recent findings highlight the operational feasibility of nuclear-powered vessels. ABS, in collaboration with Herbert Engineering, has explored ship configurations powered by microreactors, demonstrating significant advantages in fuel longevity. One such concept involves a 15,000 TEU container ship that could sail for 25 years without the need for refuelling.

Further expanding the application of SMR technology, ABS and Herbert Engineering have also proposed the use of floating reactors to power coastal AI data centres. These systems would benefit from natural water sources for efficient cooling of both server and reactor systems, addressing escalating energy demands while relieving strain on conventional power grids.

Momentum is building across the maritime industry. Key stakeholders, including Lloyd’s Register, CORE POWER, Maersk, Fincantieri, and RINA, are actively investing in nuclear feasibility studies and ship concepts. However, widespread adoption will require strategic alignment on regulation, insurance, training, and public engagement.

“The ultimate boundary condition for this technology will be safety, and we need to ensure we engage and educate the public about the advanced safety performance of these new reactors.”

Christopher J. Wiernicki, ABS Chairman and CEO.

From digital shipyards to floating nuclear innovation, ABS continues to lead industry efforts in modernising the global maritime landscape while aligning with long-term decarbonisation goals.

Want to meet key players in shipbuilding and port operations? Get in touch to discover how our MTB Shipyards and MTB Ports & Terminals events can help you build valuable industry relationships.